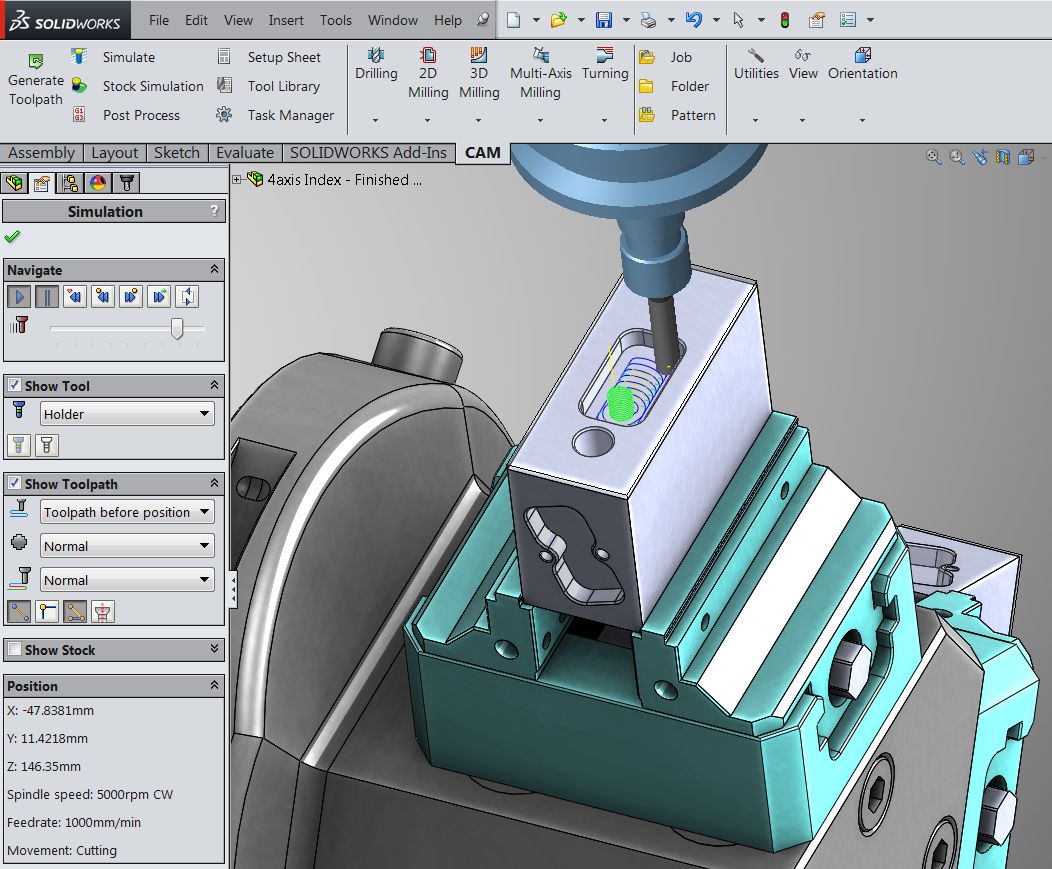

Enhanced multicore support and improved linking make adaptive clearing the most advanced adaptive roughing technology to date. Using constant tool engagement and optimized cutter paths, HSMWorks drastically reduces roughing time compared to conventional roughing and increases tool life. Engineering change orders no longer mean missing delivery deadlines or introducing last minute programming errors.Īdaptive clearing is an advanced roughing strategy that sets the bar for efficient, high volume material removal. Design changes in the CAD model get automatically updated in downstream data such as drawings and toolpaths, saving you valuable time and resources. Selecting entities directly from the SOLIDWORKS model. Machining geometry and parameters can be defined by HSMWorks allows you to maintain full associativity between the SOLIDWORKS model and machining operations. Seamless workflow from design to manufacturing In addition to all the standard toolpath strategies for milling and turning operations, HSMWorks includes advanced features such as adaptive clearing, integrated simulation and verification tools, plus a powerful post processor system that drastically reduce programming time. HSMWorks provides a fully integrated CAM solution for SOLIDWORKS®, allowing you to get up to speed and become productive within minutes using familiar tools and workflows. Achieve higher productivity, reduced costs, and shorter time to market using HSMWorks, a part of the Autodesk Product Design & Manufacturing Industry Collection.

0 kommentar(er)

0 kommentar(er)